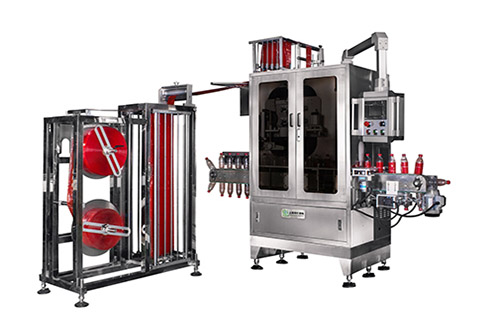

With the advancement of technology, an automatic sleeve labeling machine has emerged, which has driven the rapid development of related industries. The automation technology and high-efficiency working methods all reflect the unique charm of the automatic sleeve labeling machine, and the continuous advancement of science and technology, allowing automatic sets. The standard equipment is at the forefront of the market, and the unique advantages of the automatic labeling machine have won the favor of customers.

The automatic sleeve labeling machine not only has perfect sleeve labeling, but also has high efficiency and high labeling quality. The automatic sleeve labeling machine is the customer's effective assistant, which greatly saves the cost and increases the benefit for the enterprise. The enterprise adopts the automatic sleeve labeling machine, which requires only a small number of personnel and a small workshop area. The equipment can work uninterrupted for a long time, with high production efficiency and high return efficiency. At the same time, the labeling accuracy is also high, and there is basically no error.

The automatic sleeve labeling machine is easy to operate, easy to clean, corrosion resistant and not easy to rust. The automatic sleeve labeling machine has a wide range of applications: food and beverage, daily chemicals, electronic products, cosmetics, etc. can be used for labeling by automatic sleeve labeling machine. The automatic sleeve labeling machine can meet the needs of different industries. However, many companies are not familiar with the labeling machine. Although they have learned to operate the automatic labeling machine, they often neglect the maintenance and maintenance of the automatic labeling machine. The automatic cleaning and maintenance of the automatic labeling machine can make the automatic labeling machine more Work well and extend its useful life.

Daily maintenance of the automatic sleeve labeling machine: Do not use cleaning tools that damage the surface of the equipment, do not use corrosive plastic utensils, clean the lens of the sensor with a soft brush or cloth, pay attention to rust prevention, spray each stainless steel and iron with anti-rust oil Piece of body and gently wipe with a soft cloth.

Regular inspection and maintenance: Regular inspection of the automatic sleeve labeling machine to keep the machine running properly, remove discarded paper dust and debris, remove grease from the rollers and edges, replace the fuses regularly, use AC power and use fuses to prevent overload During the operation, it is strictly forbidden to put water droplets in the machine to prevent the machine from rusting and electric shock.

The above is the recommendation of the manufacturer of Suren mechanical sleeve labeling machine. If you understand these, you can make the automatic sleeve labeling machine reach the best condition and the service life will be longer.

Contact: Wendy Jiang

Phone: 0086-13482266656

Tel: 0086-21-33657068

Email: sales03@sr-packing.com

Add: No. 18, Changting Road, Fengxian District, Shanghai, China